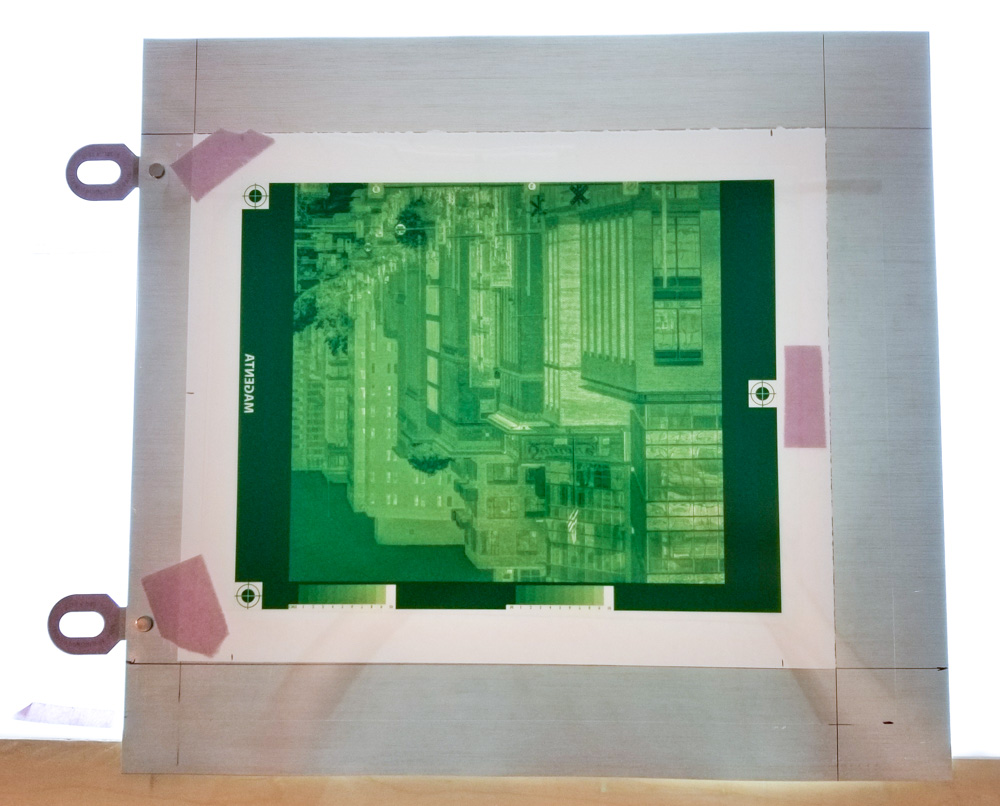

I’m in the process of revisiting tri-color gum bichromate printing and wanted to create a viable pin registration system. Here’s what it looks like with a negative. The paper is mounted onto aluminum using Fusion 4000 dry mount film and a heat press.

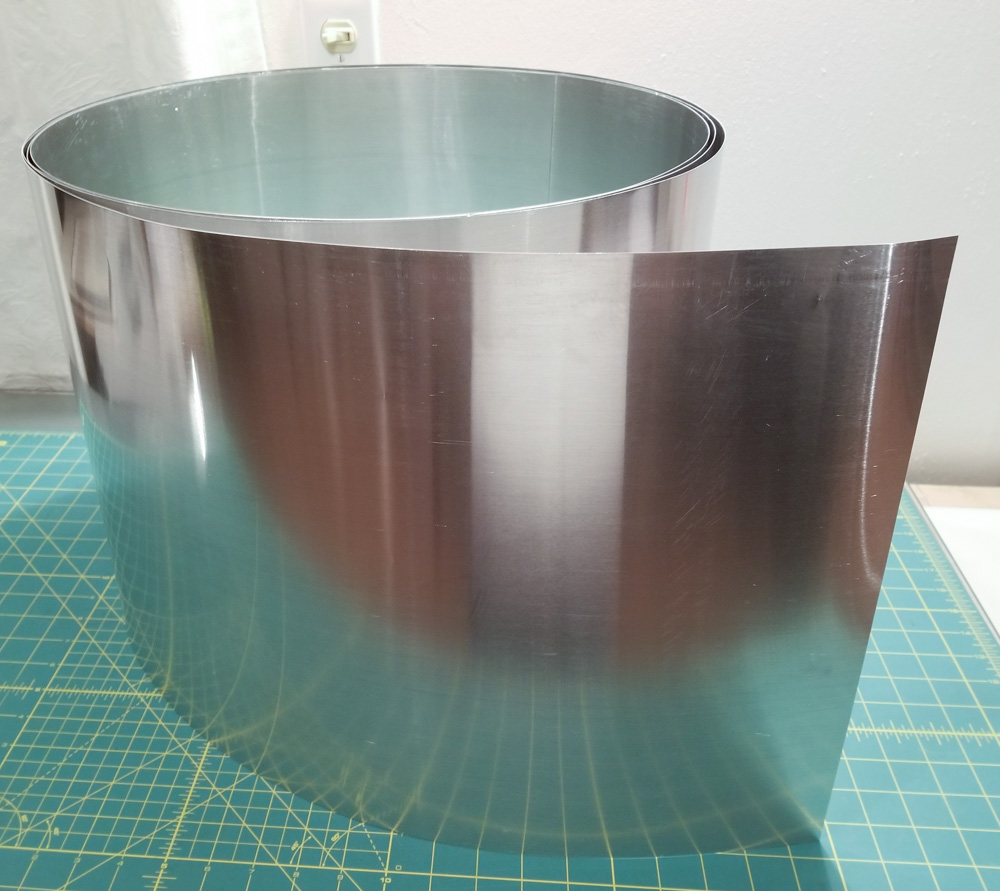

A sheet of 0.010″ aluminum flashing from the local hardware store serves as a ridged base to keep the paper from stretching or shrinking during the three-plus hours of water bath development . . .

And a hole punch from the now-defunct “Staples” office supply. I modified the carriage to allow a larger opening on each side. First, I punch holes in the thin aluminum, then into all three carrier sheets simultaneously for proper alignment.

It punches a 9/32″ hole to precisely match the Ternes-Burton pins.

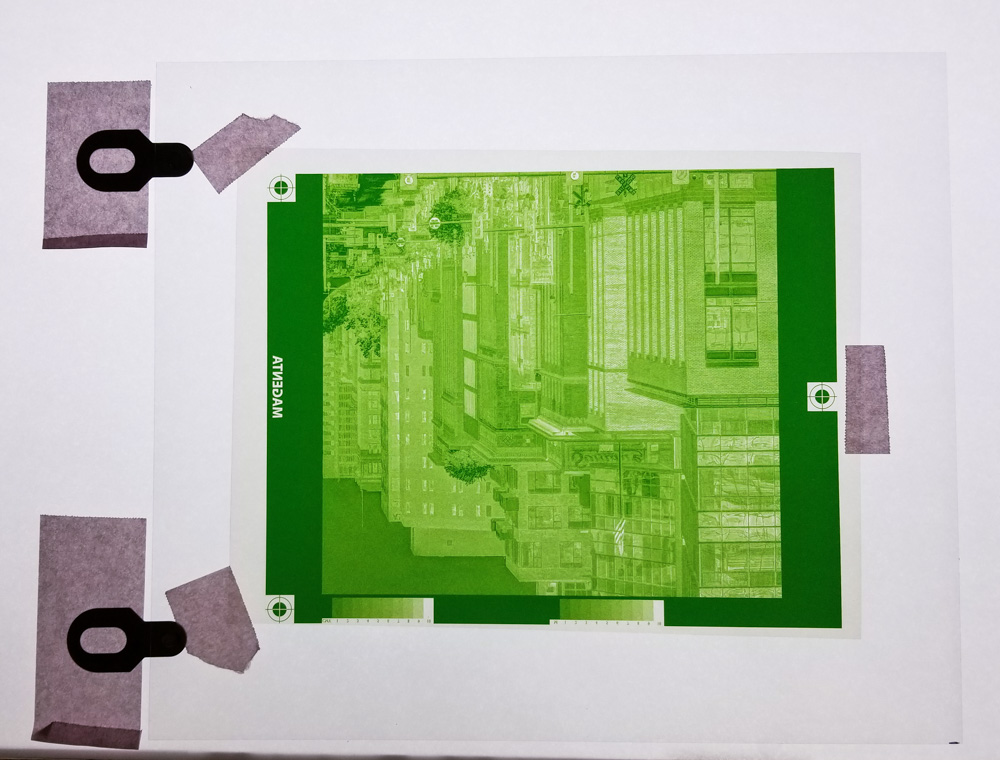

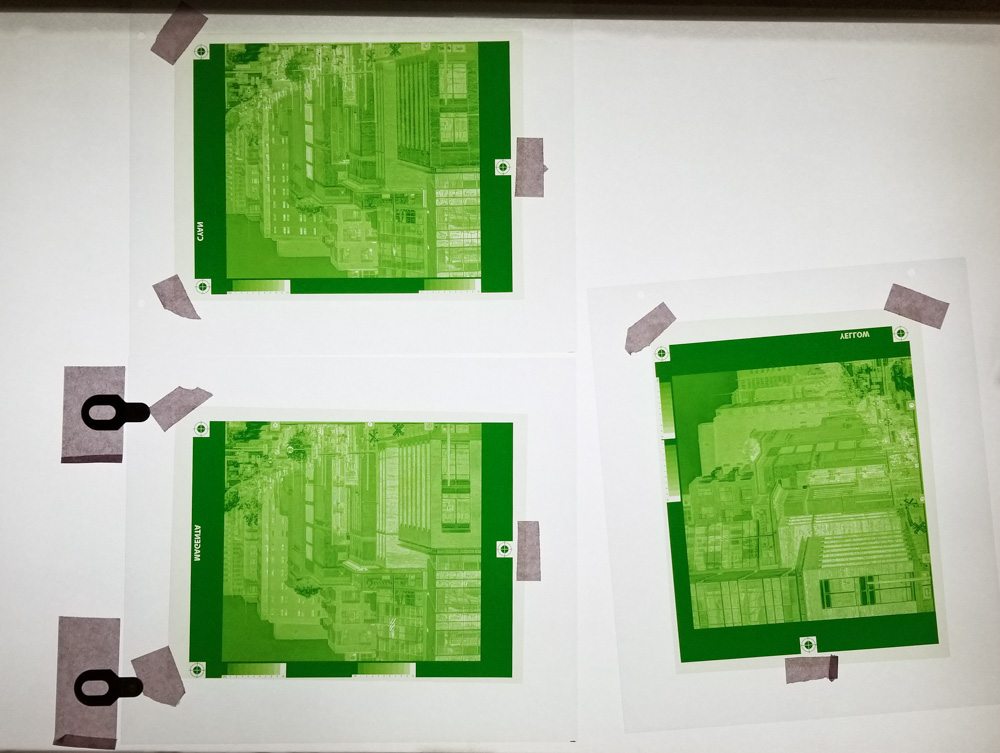

I begin with a 0.007″ Duralar carrier sheet for each of the negatives. The carrier is placed down on the two pins, and a negative is aligned and taped onto the carrier. Then a second carrier is placed on top of these and the second negative is aligned and taped to its carrier. Finally, the second film is removed and the final carrier is placed on top of the first and the third negative is aligned and taped.

Here, all three negatives have been secured to a carrier sheet and are ready for printing. For each color, I install the pins into holes in the aluminum sheet, attach a carrier sheet (with negative) onto the pins and tape the sheet down to the metal. The pins are then removed and the exposure is made.

Does it work? I hope to find out this weekend. This system has been adapted from a video I found by Newman Company on silkscreen printing. Here’s the link: